TECHNOLOGY

Elve is the world’s leading innovator within the manufacturing, design, and applications of mmWave power.

Relentless.

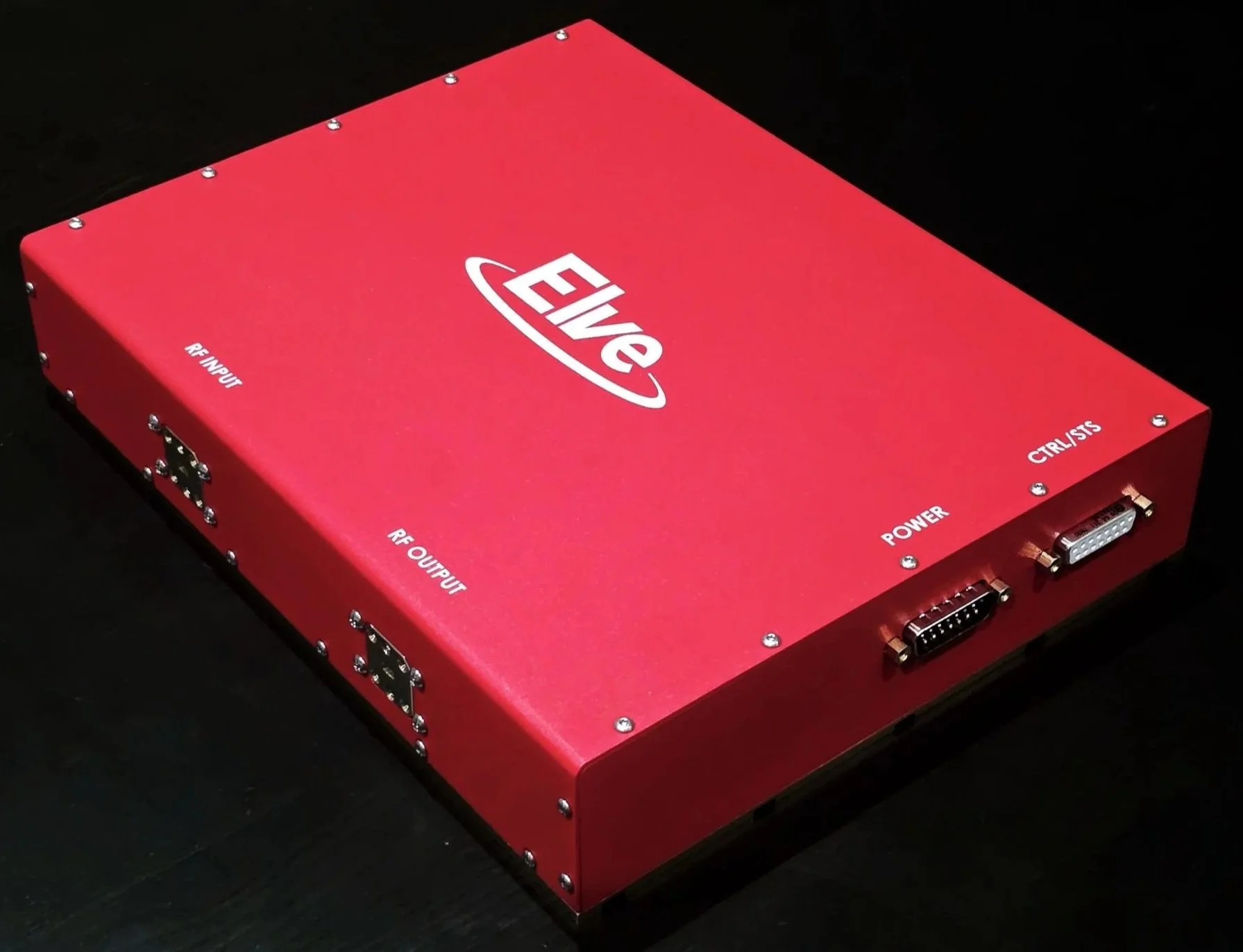

Elve TWTAs are built to perform without compromise—compact, efficient, and powerful across every environment and platform. SWaP-C (size, weight, power, and cost) optimization enables interoperable, redundant systems that thrive in the most demanding domains.

By refining the sheet electron beam architecture, we extract more power from smaller footprints, maximizing output while minimizing form factor. Operating in ultra-high vacuum, our TWTAs are not constrained by the Johnson limit and maintain superior power density even through adverse conditions such as weather or dust storms.

Electron energy recovery collectors coupled with folded waveguide circuits enable high-efficiency performance and cost effectiveness — delivering TWTA capability at SSPA pricing.

Reliable.

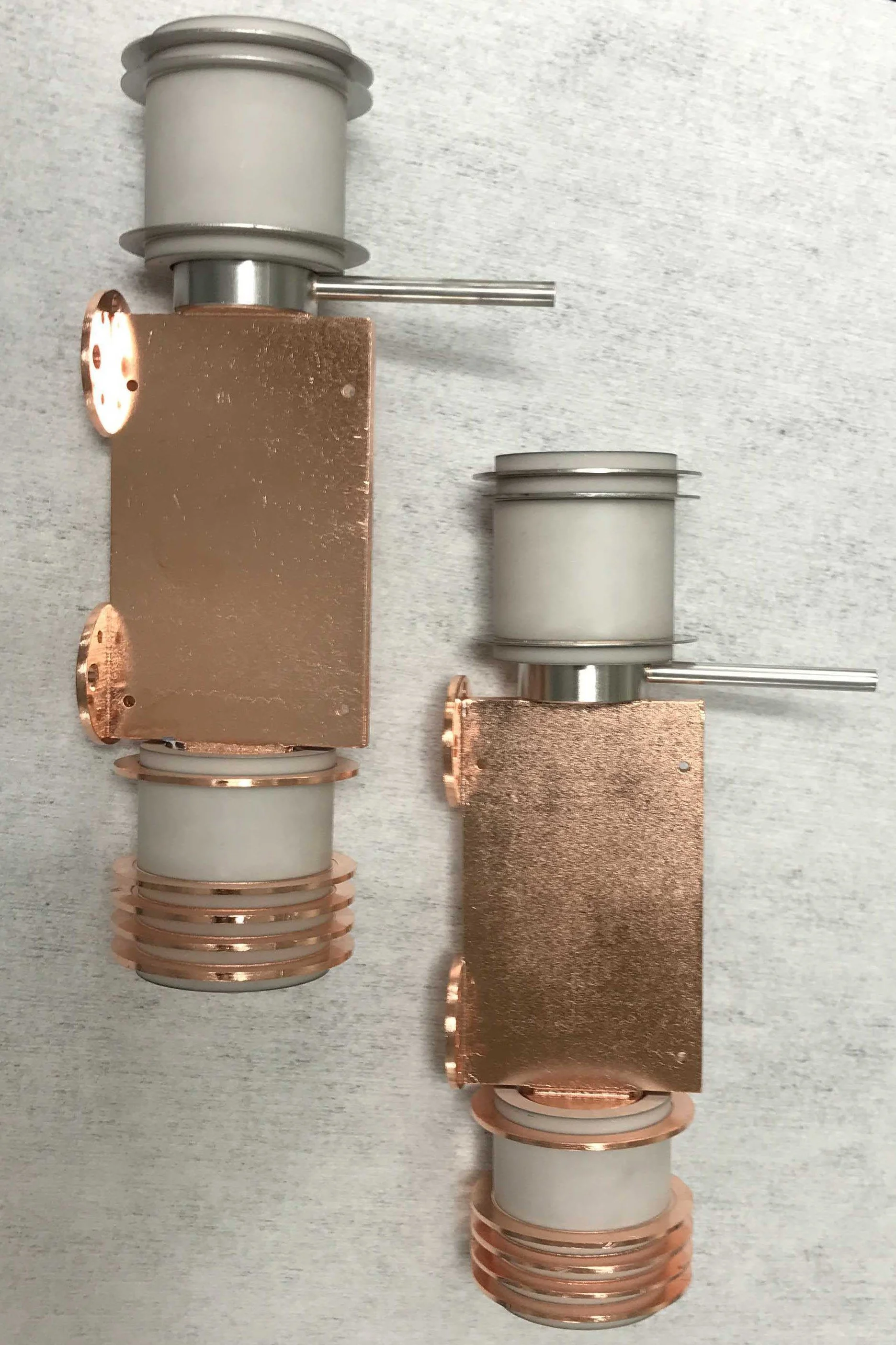

Long-lifetime emitters are the foundation of dependable TWTA performance. Electron emission quality and continuity directly determine amplifier quality and lifespan — a fact proven by TWTAs that have operated for decades, including those aboard the Voyager probes.

In high-performance systems, such as mmWave (millimeter-wave) TWTAs, emitter materials are often driven to extreme temperatures to achieve high current density. Elve emitter technology eliminates this tradeoff. From nanocomposite scandate tungsten powder synthesis to final integration with the heating element, we engineer every stage in-house. Our patented high current density material matrix, combined with barium calcium aluminate, delivers high performance at significantly reduced operating temperatures — maintaining performance over decades.

Resilient.

ELve TWTA’s metal-ceramic construction delivers the strength and stability that high-performance systems demand. Each design is qualified to military and space standards, proven through exhaustive shock, vibration, and temperature cycling tests. Elve TWTAs maintain consistent performance across the harshest environments. Built for resilience, tested for endurance, and trusted where reliability is non-negotiable.

Repeatable.

Elve redefines how TWTAs are manufactured — transforming a traditionally handcrafted process into a scalable, high-quality manufacturing platform. What once demanded intricate assembly and extensive manual alignment is now achieved through digitally controlled, automated workflows that ensure consistency from prototype to production.

Leveraging advanced additive manufacturing, precision materials processing, and intelligent automation, Elve delivers unprecedented uniformity across builds and frequency bands. Our approach enables mmWave (millimeter-wave) TWTAs to be produced efficiently, repeatably, and at scale — turning what was once an artisanal process into a true manufacturing technology.