Electron Bits

Sharing our knowledge is one of Elve Values.

What is a TWTA?

A Traveling Wave Tube Amplifier (TWTA) is an essential technology enabling compact, high-power millimeter-wave (mmWave) amplifications. TWTAs have been used in space applications for decades, demonstrating their exceptional robustness and suitability for harsh operating environments. These vacuum electronic devices amplify signals through the interaction between an electron beam and a slow-wave radio frequency (RF) circuit structure. By matching the electron beam velocity to the signal velocity, beam energy is efficiently converted into RF power.

With efficiencies exceeding 50%, TWTAs have long served as the backbone of space communications. This high efficiency is achieved in part through the use of a depressed collector, which sorts the electron beam onto biased electrodes after amplification to recover a significant portion of its energy.

Elve TWTAs employ sheet electron beams with an elliptical cross-section, offering several advantages including compactness, robustness, and ease of manufacturing.

Which to choose: SSPA or TWTA?

High performance mmWave systems need both: an SSPA and a TWTA!

SSPAs offer a low power solution as a pre-amplifier, where low efficiency and lack of compactness plays a minor role. To close the link and reach high performance, TWTAs offer high power with high efficiency in a compact form.

SSPAs based on GaN technology were introduced about a decade ago and offer an affordable solution for up to multi-Watt scale systems, where <10% efficiency does not significantly impact size, energy draw, and thermal management of the overall system. Let’s consider two basic examples:

(1) A 1 W SSPA will draw about 10 W of power requiring 9 W of thermal dissipation occupying roughly 140 cm3 of space. There is no TWTA technology available yet offering such low power levels, and hence the system cannot yet benefit from the high efficiency of the TWTA tech.

(2) A 100 W SSPA will draw about 1 kW of power requiring 900 W of thermal dissipation occupying roughly 14,000 cm3 (or ~14 liters) of space. A 100 W TWTA available today would draw less than 300 W of power requiring 200 W of thermal dissipation and occupying less than 2,500 cm3 (or ~2.5 liters) of space.

What about a 25 W system, you may ask?

(3) A 25 W SSPA will draw more than 250 W of power requiring 225 W of thermal dissipation occupying roughly 3,500 cm3 (or ~3.5 liters) of space. A 25 W TWTA available in 2026 would draw less than 75 W of power requiring 50 W of thermal dissipation and occupying less than 1,500 cm3 (or ~1.5 liters) of space.

Let’s consider operating costs as well: at $0.20 per kW-h, every 1 Watt of transmitted power from an SSPA costs $17.52 per year; every 1 Watt from a TWTA costs $5.26 per year.

Both SSPAs and TWTAs offer operating lifetimes of over 100,000 hours (roughly ten years). Historically, though, TWTAs have had the disadvantage of being very difficult to manufacture, meaning that volumes produced have been low and prices have been high. Thanks to Elve’s new technology advancements, high quality and high performing TWTAs are now available in volume and at an affordable price.

In conclusion, as long as there is a TWTA option, it will offer huge system advantages in size, weight, power, and efficiency. To complete the system, it is convenient to utilize a low power SSPA as a pre-amplifier.

Modern TWTAs: Fast, Reliable, and Built the Elve Way

For decades, TWTAs have powered the world’s most advanced communications and radar systems — but they have also had a reputation for being slow to produce, fragile, and costly.

Elve is changing that.

At Elve, we build TWTAs the modern way.

Our TWTs use a folded waveguide structure that is extremely robust and easy to scale.

We are a vertically integrated TWTA manufacturer (from cathodes to power supplies!).

We focus on design for manufacturing (DFM) methodologies.

We make speed, reliability, and scalability part of the process from day one.

Our amplifiers are frequency-agnostic, designed through advanced modeling and manufactured using additive techniques that minimize tuning and enable rapid turnaround. What once took months to design and assemble can now be brought from concept to full power in just 15 days.

Reliability is designed in, not added later. Elve’s use of patented nanocomposite scandate cathode materials allows for tight thermal management, and consistent process controls deliver relentless dependable performance. Whether it’s a high power application lasting 200 hours or more, or a GEO mission lasting 15 years or longer, we've got it covered as part of our robust design process.

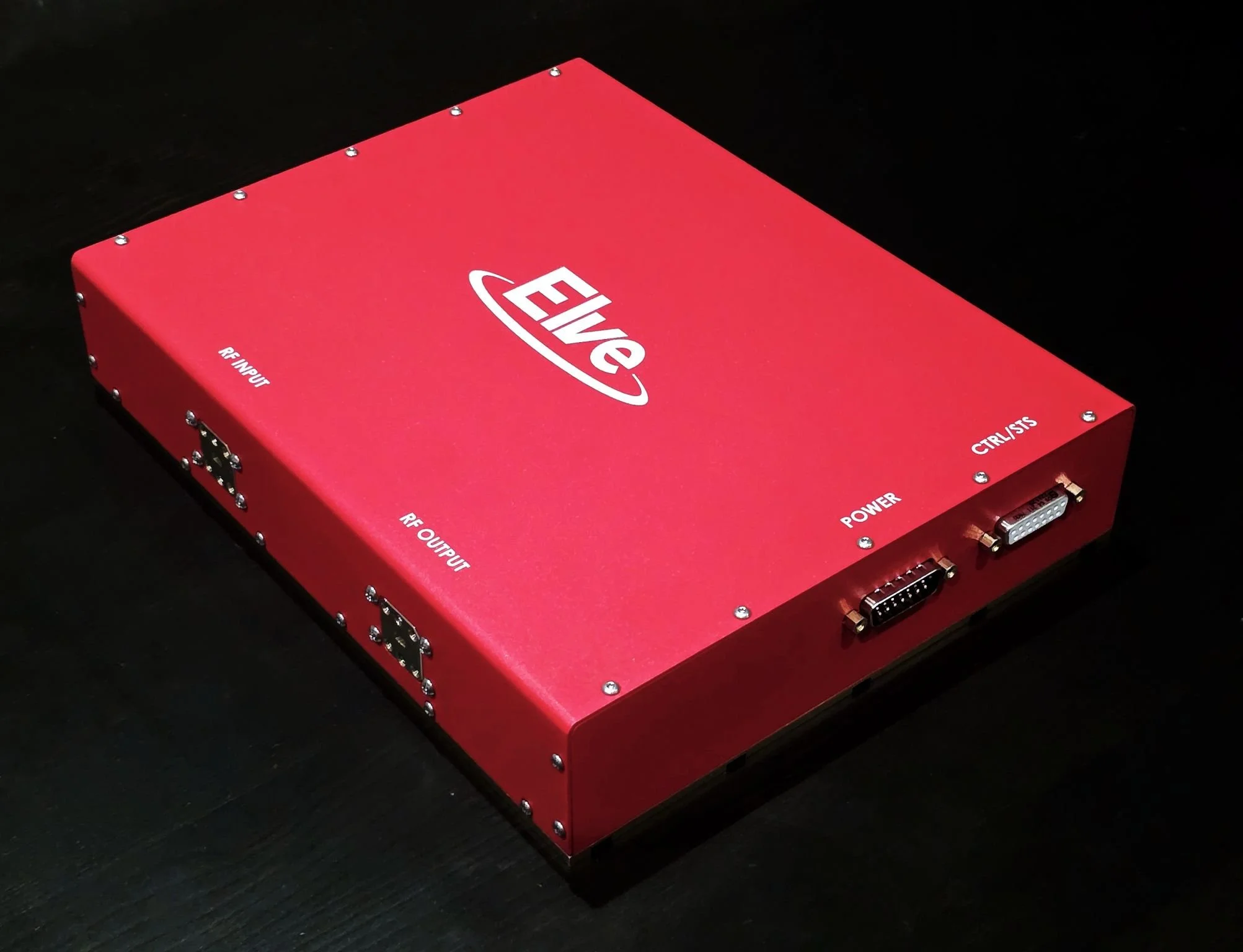

Compact, efficient power conditioning further reduces size, cost, and complexity. The result is a new class of TWTAs: fast to build, reliable, and ready for the next generation of mmWave applications. Elve is redefining what vacuum electronics can be — not old technology revived, but new technology realized.

Why mmWave for high data rate connectivity?

The millimeter wave (mmWave) portion of the electromagnetic spectrum offers a number of compelling advantages over the more mature microwave bands for communication and sensing applications. For communications, operation at high frequencies offers access to wider bandwidths where data rates of 10 Gbps and larger are achievable. For sensing, resolution is proportional to the operating wavelength offering ability to image and detect sub-centimeter scale objects. Furthermore, antenna size requirements are reduced for a given antenna gain enabling compact systems suitable for deployment on small space platforms. Applications for mmWave power amplifier modules in space include weather mapping, earth surface and underground imaging, space-debris detection, backhaul, intersatellite communications.

Unlike lasercom, which suffers from severe weather susceptibility, complex pointing requirements, and a lack of readily available space-qualified hardware, mmWave communication provides a robust, all-weather solution that integrates seamlessly into existing satellite architectures. The mmWave systems operate from a DC bus, making them highly compatible with modern small satellite platforms, while their conduction-cooled design ensures reliable thermal management even in the harsh environments of Low Earth Orbit (LEO).

Compared to lasercom, mmWave communications systems are a proven technology, available today, and capable of supporting mission-critical downlinks and intersatellite links without the need for precise optical alignment or vulnerability to atmospheric disruptions. These mmWave systems have undergone extensive qualification testing, including radiation exposure, thermal cycling for operation from -40°C to +65°C, and launch-induced shock and vibration, ensuring long-term reliability for space applications.